Introduction

Setting time of cement describes the time of stiffening of the cement paste. This is the time at which the cement mix changes from plastic state to a solid state. It should be noted that there is no necessary relationship between the setting time of cement and its hardening, which is the strength gain in a set cement paste, even though with setting comes strength. In fact, slow setting cement may harden more rapidly than a quick setting one, and vice versa.

The setting time of cement is described with two terms:

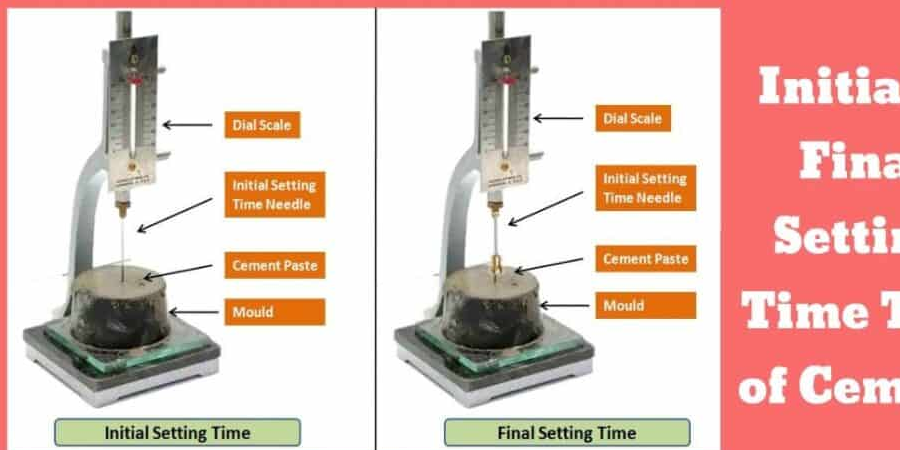

- Initial Setting Time: This is the time taken by paste to stiffen to such an extent that the Vicat’s needle is only permitted to penetrate the paste to 25 mm or less.

- Final Setting Time: This is the time after which the paste becomes so hard that Vicat’s 5mm needle doesn’t penetrate it visibly and leave no impression.

Objective(s) of the Experiment

The experiment is carried out to determine the initial and final setting time of cement using Vicat’s apparatus.

Equipments and Materials Needed

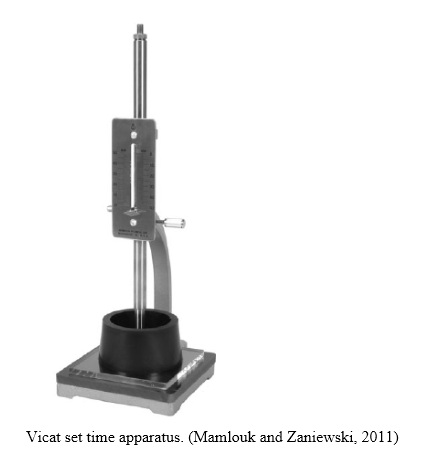

- Vicat’s apparatus: As shown below, this apparatus consists of a frame with a movable rod; and it has a removable needle of diameter 1mm, which is used in the determination of the initial setting time; another needle of diameter 5mm, which is used in the determination of the final setting time; and a base plate.

- Weighing Balance

- 400g sample of cement

- Conical hard rubber ring

- Trowel

- Measuring Cylinder

- Water

Procedures

Preparation of Sample

- Weigh 400g of cement using the weighing balance and a pan (Remember to determine the weight of the pan first and deduct this from the final weight)

- Measure 120ml of water using the graduated measuring cylinder

- Add this water to the cement powder and using the hand trowel, mix the sample thoroughly to form a paste. Make sure that the time taking for making the paste does not exceed one minute.

Determination of Initial Setting Time

- Fill the hard conical rubber ring with the cement paste and level it with the hand trowel.

- Set the 1mm diameter needle on the lower end of the rod.

- Now release the rod for 30 seconds and note the time at which the needle was released, record this along with the penetration of needle in the paste.

- After 15 minutes, again release the rod for 30 seconds and note the penetration of the needle in paste.

- Repeat the above step until the penetration becomes just 25 mm or less (and record the time and penetration for each repitition).

- By interpolation, the time when a penetration of 25 mm occurs is determined and recorded as the initial set time.

- Compare it with the standard time and give comments.

Determination of Final Setting Time

- Fill the hard conical rubber ring with the cement paste and level it with the hand trowel.

- Set the 5mm diameter needle on the lower end of the rod.

- The final setting time of cement is determined as the time at which the released needle cannot visibly penetrate or make an impression on the surface of the paste.

- Compare it with the standard time.

- The final setting time can be found using the formula:

Final Setting Time = 90 + 1.2 (Initial Setting Time); in minutes.

ASTM Standards for Setting Time

- Initial Setting Time: 49 minutes to 202 minutes; with 25mm penetration

- Final Setting Time: 185 minutes to 312 minutes; with no penetration

Discussions and Conclusion

- Gypsum is a compound added to cement during production to regulate the setting time of cement

- Factors like water-cement ratio, fineness of cement, and admixtures present affect the set time of cement

- Exposure of the cement to humidity during storage may instigate the occurrence of a false set, in which the cement stiffens within a few minutes of being mixed, without the evolution of much heat. To resolve this problem, the cement paste can be vigorously remixed, without adding water, in order to restore plasticity of the paste and to allow it to set in a normal manner without losing strength.

- If the availability of aluminate ions is high, and sulfates are low, either a quick set (10 to 45 minutes) or flash set (less than 10 minutes) can occur.

- False set can be resolved by remixing, whereas a quick set and a flash set cannot be remedied.

References

- Haidar, B. (2015). “Experiment No: 2. To Determine the Initial and Final Setting Time and Consistency Of Cement”. Laboratory Instruction Manual for CE216: Building Materials & Concrete Technology, Civil Engineering Department, Ishik University.

- Mamlouk, M.S. And Zaniewski J.P. (2011). “Materials For Civil and Construction Engineers”.