Introduction

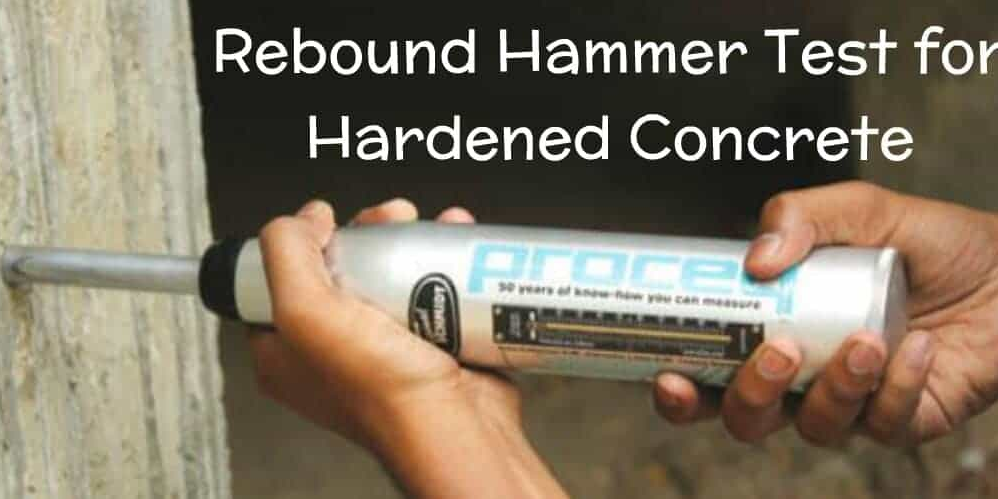

In this test, a steel hammer impacts with a predetermined amount of energy, a steel plunger in contact with a surface of concrete, and the distance that the hammer rebounds is measured.

Significance of the Test

- This test method may be used to assess the in-place uniformity of concrete, to delineate regions in a structure of poor quality or deteriorated concrete, and to estimate in-place strength development.

- This test is used to estimate strength requires by establishing a relationship between strength and rebound number. The relationship shall be established for a given concrete mixture and given apparatus.

- The test can also be used to determine when forms and shoring may be removed.

Test Area

Concrete members to be tested shall be at least 100 mm (4 in.) thick and fixed within a structure. Smaller specimens must be rigidly supported. Areas exhibiting honeycombing, scaling, or high porosity should be avoided. The form material against which the concrete was placed should be similar. Troweled surfaces generally exhibit higher rebound numbers than screeded or formed finishes. If possible, structural slabs should be tested from the underside to avoid finished surfaces.

Objective(s) of the Experiment

The test is carried out to determine the rebound number of hardened portland cement concrete.

Equipment

Rebound Hammer

Procedures

- Grind and clean the concrete surface by rubbing with the abrasive stone that accompanies the rebound device.

- Firmly hold the instrument in a position that allows the plunger to strike perpendicularly to the test surface.

- Gradually increase the pressure on the plunger until the hammer impacts.

- After impact, record the rebound number to two significant digits.

- Take 10 readings from each test area.

Conditions for Test

- No two impact tests shall be closer together than 25 mm (1 in.).

- Discard the reading if the impact crushes or breaks through a near-surface air void.

- Discard readings differing from the average of 10 readings by more than 7 units, and determine the average of the remaining readings.

- If more than two readings differ from the average by 7 units or more, discard all readings.

- The rebound hammer should be periodically serviced and verified using metal anvils, according to manufacturer recommendations.

Results

The following information is recorded for each test:

- Date and time of testing.

- Identification of location tested in the concrete construction and the type and size of member tested.

- Description of the concrete mixture proportions including type of coarse aggregates if known.

- Design strength of concrete tested.

- Description of the test area including:

- Surface characteristics (trowelled, screeded) of area.

- If surface was ground, and depth of grinding.

- Type of form material used for test area.

- Curing conditions of test area.

- Type of exposure to the environment.

- Hammer identification and serial number.

- Air temperature at the time of testing.

- Orientation of hammer during test.

- Average rebound number for test area, and

- Remarks regarding discarded readings of test data or any unusual conditions.

Discussion and Conclusion

For readings to be compared the direction of impact, horizontal, downward, upward, etc., must be the same or established correction factors shall be applied to the readings.

Different hammers of the same nominal design may give rebound numbers differing from 1 to 3 units and therefore, tests should be made with the same hammer in order to compare results. If more than one hammer is to be used, a sufficient number of tests must be made on typical concrete surfaces so as to determine the magnitude of the differences to be expected.

References

- Mamlouk, M.S. And Zaniewski J.P. (2011). “Materials For Civil and Construction Engineers”.

- 2. ASTM C 805 – 97 “Standard Test Method for Rebound Number of Hardened Concrete”