Introduction

Construction aggregate, or simply “aggregate”, is a broad category of coarse to medium grained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates. Aggregates are the most mined materials in the world. Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as reinforcement to add strength to the overall composite material. Due to the relatively high hydraulic conductivity value as compared to most soils, aggregates are widely used in drainage applications such as foundation and French drains, septic drain fields, retaining wall drains, and road side edge drains. Aggregates are also used as base material under foundations, roads, and railroads. In other words, aggregates are used as a stable foundation or road/rail base with predictable, uniform properties (e.g. to help prevent differential settling under the road or building), or as a low-cost extender that binds with more expensive cement or asphalt to form concrete.

Why do we need to determine the aggregate crushing value?

The principal mechanical properties required in aggregates are:

- Satisfactory resistance to crushing under the roller during construction

- Adequate resistance to surface abrasion under traffic

Aggregates that are used in road construction and other engineering construction processes should be strong enough to resist the load they are being subjected to. In road, if the aggregates are weak, the stability of the pavement structure is likely to be greatly adversely affected. The strength of coarse aggregate is assessed by the aggregate crushing test. The aggregate value provides a relative measure of resistance to the crushing under a gradually applied compressive load. To achieve a high quality of pavement, aggregate possessing low aggregate crusghig value should be preferred.

Objective(s) of the Experiment

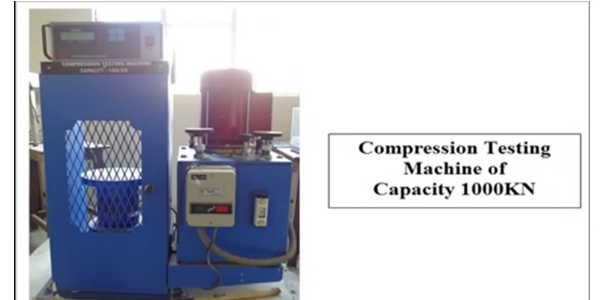

This test is carried out to determine the aggregate crushing value using a compressive testing machine

Equipments and Materials Needed

The equipments and materials needed for aggregate crushing test are:

- Compressive Testing Machine capable of applying load of 40 tonnes, at a uniform rate of loading of 4 tonnes per minute.

- Steel cylinder with open ends, and internal diameter 152mm, square base plate, plunger having a piston of diameter 150mm, with a hole provided across the stem of the plunger so that a rod could be inserted for lifting or placing the plunger I the cylinder.

- Cylindrical measure having internal diameter of 115mm and height 180mm.

- Steel tamping rod with one rounded end, having a diameter of 16mm and length 450mm to 600mm.

- Weighing Balance of capacity 3kg with accuracy up to 1gm.

Procedures

- About 6.5kg of aggregate is required for preparing two test samples. The aggregate passing 12.5mm IS sieve and retained on 10mm IS sieve is selected for standard test. The aggregate should be in surface dry condition before testing. The aggregate may be dried by heating at a temperature of 100oC to 110oC for a period of 4 hours and is tested after being cooled to room temperature.

- The cylindrical measure is filled by the test sample of aggregate in three layers of approximately equal depth, and each layer tamped 25 times by the rounded end of the tamping rod. After the third layer is tamped, using the tamping rod as a straight edge, level off the aggregate at the top of the cylindrical measure.

- The sample is then weighed as W1

- The cylinder of the test apparatus with open ends is then placed on the base plate; one third of the test sample is placed in this cylinder and tamped 25 times by the tamping rod. Similarly, the other two parts of the test specimen are added and each layer subjected to 25 blows.

- The surface of the aggregate is leveled and the plunger is inserted so that it rests on its surface in leveled position.

- The cylinder with the test sample and the plunger in position is placed on the compression testing machine.

- Load is applied through the plunger at a uniform rate of 4 tonnes per minute until the total load is 40 tonnes, and the load is released.

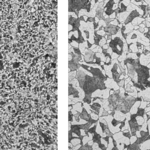

- Aggregates including the crushed portion are removed from the cylinder and sieved on a 2.36mm IS sieve. The material which passes this sieve is collected and weighed as W2.

- The above procedures are repeated on a second sample of the same weight. Thus two tests are made for the same specimen for taking an average value.

Results and Calculations

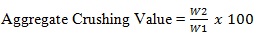

The aggregate crushing value is defined as a ratio of the weight of fine passing the specified IS sieve to the total weight of the sample expressed as a percentage:

Where

W1 = Total weight of dry sample

W2 = Weight of the portion of the crushed material passing 2.36mm IS sieve

The mean of the crushing value obtained in the two tests is reported as the aggregate crushing value (A.C.V.)

Discussion and Conclusion

- The aggregate crushing value for cement concrete pavement shall not exceed 30%

- The aggregate crushing value for wearing surfaces shall not exceed 45%

- IS: 2386 – Part 4. “Aggregate Crushing Value Test”.

- Wikipedia (2018). “Construction Aggregate”. http://en.wikipedia.org/wiki/Construction_aggregate. Accessed February 24, 2018.