Introduction

The dry density of the compacted soil or pavement material is a common measure of the amount of the compaction achieved in the field during compaction. Knowing the field density and field moisture content, the dry density is calculated. Therefore, in-situ density (or field density) test is important as a field control test for the compaction of soil or any other pavement layer.

There are several methods for the determination of in-situ density of soils. They include: core-cutter method, sand bottle replacement method, rubber balloon method, heavy oil method, etc. For this section, the sand bottle replacement method is considered.

The basic principle of sand replacement method is to measure the in-situ volume of hole from which the material was excavated from the weight of sand with known density filling in the hole. The in-situ density of the material is given by the weight of the excavated material divided by the in-situ volume.

Objective(s) of the Experiment

The test is carried out in order to determine the relative compaction of the soil, that is, how well the soil compacted is on site as compared to the laboratory compaction to attain the desired maximum density.

Equipments and Materials Needed

The equipments and materials needed for the oven drying method are listed below:

- Calibrated sand (e.g Ottawa Sand)

- Sand replacing cylinder and density tray

- Weighing scale

- Speedy moisture tester

- Calcium carbide powder

- Mallet or hammer

- Steel pegs, spoon, can and chisel.

Some of the materials such as the calibrated sand and the calcium carbide powder need to be prepared in the laboratory before the site test is carried out.

-density-test-pic6.jpg)

Preparation of calibrated sand

- Fine aggregate (sharp sand from river bank) is collected.

- The sand is dried to minimal moisture content.

- The sand retained on 300 µm sieve size is used for the test, with the bulk density of the sand calculated and also the weight of sand in cone known.

Preparation of calcium carbide

Lump of calcium carbide is available in market, this is grinded to powder and the powder is sieved with sieve size 425 µm. The particles that pass through this sieve are used for the test.

Procedures

- On the road to be tested, points at which the test would be done are identified and marked out.

- At each point, the density tray is placed on a smooth flat surface and with the aid of a mallet and four steel pegs; the tray is affixed firmly on the chosen point.

- With the help of a mallet, chisel, and the circular hole on the density tray, a hole of diameter 10 mm and a depth of 15 mm within the grade of the soil is dug. It is worth of noting that during the process of digging, if a different layer (of grade) of soil reached before the 15 mm depth, digging should stop. Two layers must not mix together during test.

- The soil removed the hole is weighed and recorded as the weight of soil from hole.

- Calibrated sand is then poured into the cylinder to full and then weighed. The weight is recorded as the weight of sand before pouring.

- The cylinder containing the sand is then placed gently to set the center of the hole dug with the tray still on the ground. The lid of the cylinder is then opened from the bottom and sand is allowed freely into the hole.

- Once it is observed that the hole is filled, the opening is locked and the weight of the sand remaining is taken. This is recorded as the weight of sand remaining after pouring.

- The moisture content is determined by the help of the speedy moisture tester and calcium carbide. This is the speedy moisture content and is recorded as m’.

- Steps (b) – (h) are carried out on other points to be tested.

-density-test-pic7.jpg)

Results and Calculations

Definitions of some important terms used are given below.

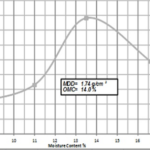

- Laboratory maximum dry density (M.D.D.) is gotten from the compaction test.

- Bulk density of the calibrated sand is also determined

- Weight of sand in the cone is also determined in the laboratory.

- Weight of sand in hole = (Weight of sand before pouring) – (Weight of sand after pouring + Weight of sand in cone).

- Actual moisture content

-density-test-pic1.jpg)

-density-test-pic2.jpg)

-density-test-pic3.jpg)

-density-test-pic4.jpg)

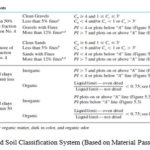

An example of the sheet on which the in-situ density test computations are done is shown below

-density-test-pic5.jpg)

Discussion and Conclusion

Based on specification, relative compaction should not be less than 95%, although as low as 90% may be allowed. It is recommended that points with ‘poor’ and ‘fair’ remarks should be compacted again before pavement is laid.

Insitu (Field) Density Test (0 downloads )