Introduction

For bituminous mixes, determination of the content is considered to be one of the important facets of quality control during highway and airfield construction, and it is achieved by extracting bitumen from the bituminous mix. Kerosene is used as a solvent in the extraction of bitumen from bituminous mixes (http://trid.trb.org). Thus, the test is carried out to determine the bitumen content as per ASTM 2172.

Objective(s) of the Experiment

The objective of this experiment is to determine the bitumen content of an asphaltic mix

Equipments and Materials Needed

- The bituminous mix

- Centrifuge Extractor

- Kerosene

- Miscellaneous materials like bowl, filter paper, and balance.

Procedures

- If the mixture is not soft enough to separate with a trowel, place 1000g of it in a large pan and warm up to 100oC to separate the particles of the mixture uniformly, then take a sample weighing 500g (Weight ‘A’).

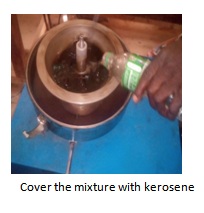

- Place the sample (Weight ‘A’) in the centrifuge extractor. Cover the sample with kerosene and put the filter paper on it with the cover plate tightly fitted on the bowl.

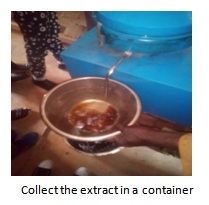

- Place a container under the outlet to collect the extract.

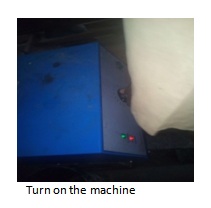

- Start the centrifuge extractor, revolving slowly and gradually increase the speed and continue adding kerosene to the mix through the perforated part of the centrifuge extractor’s cover.

- Continue the process until the extract coming from the outlet becomes clear and not darker than the light straw color and record the volume of the total extracted in the container below the outlet.

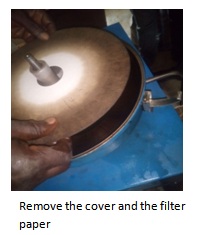

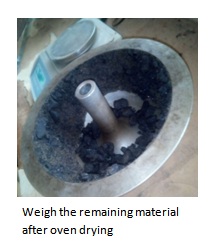

- Remove the filter paper from the bowl and dry and dry the remaining sample in the oven at 105oC – 115oC. After 24 hours, take the weight of the sample (Weight ‘B’).

The steps are shown below:

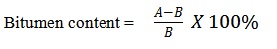

Results and Calculations

References

- http://trid.trb.org