Introduction

Cassava is the most important root crop in Nigeria. Apart from being a staple crop in both rural and urban areas, it is also a major source of income to cassava farmers and processors in the rural areas. Cassava is a major source of carbohydrate, it contains vitamins B and C. it has no protein and fat. Cassava can be made into a simple paste with water and used as a peel or scrub smoothes, brightens and hydrates the skin, cassava can also be used as thickener, glue, sweetener and in production of alcohol.

Some of the food products that can be made from cassava include fufu, lafun, garri, starch etc as discussed in this article.

1. Lafun Production

Lafun is a fibrous powdery form of cassava similar to fufu in Nigeria. The method of production of lafun is different from that of fufu. In the traditional preparation, fresh cassava roots are cut into chunks and steeped for 3-4 days or until the roots become soft. The fermented roots are peeled, broken up into small pieces, and sun dried on mats, flat rocks, cement floors, or the roofs of houses. The dried pieces are milled into flour. Alternatively, chips are made directly from fresh roots, cut into chunks, and sun dried. Drying takes 2-4 days, depending on the weather.

Objective(s) of the experiment

This procedure is carried out to produce lafun from cassava

Materials and Equipments

1. Bowl

2. Knife

3. Milling machine

4. Drying machine

Procedure

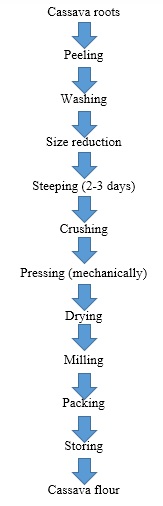

1. The raw material, cassava is peeled.

2. The size of the peeled cassava roots is reduced by cutting to allow even fermentation.

3. Soak the size reduced cassava in a bowl for about 48-72hours with daily removal of the water. This is because the water would have been filled with Hydrogen Cyanide brought about by the fermentation at room temperature.

4. The fermented cassava is then sieved, and the fibrous materials separated to control the size of particles.

5. After fermentation is complete, the cassava is pressed mechanically to drain off all water present in it.

6. The mash is then dried, milled and packaged in transparent cellophane.

The procedure is illustrated with the flow diagram below:

Results

Unlike fufu, the fibers in the retted root are dried along with the mash and later sieved out. Thus, lafun is coarse than fufu in texture. The flour is made into dough with boiling water before consumption.

Conclusion

When properly stored, lafun has a shelf-life of six months or more

2. Fufu Production

Fufu is a staple food common in many countries in Africa like Nigeria, Ghana, and Liberia. It is made into balls to go with soup or stews.

Objective(s) of the experiment

This procedure is carried out to produce fufu from cassava

Materials and Equipments

1. Weighing balance

2. Bowl

3. Presser

4. Dryer

5. Milling machine

6. Sealer

Procedure

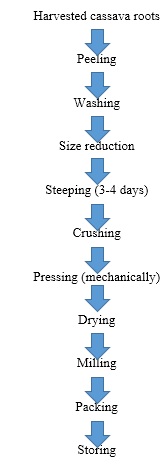

1. Peel the raw material, that is, cassava

2. The size of the peeled cassava roots should then be reduced by cutting to allow even fermentation.

3. Soak the size reduced cassava in a bowl for about 48-72hours with daily removal of the water. This is because the water would have been filled with Hydrogen Cyanide brought about by the fermentation at room temperature.

4. Sieve the fermented cassava, and separate the fibrous materials to control size of particles.

5. After fermentation is complete, press the cassava mechanically to drain off all water present in it.

6. Carry out drying, milling, and package in transparent cellophane.

The procedure is illustrated with the flow diagram below:

Results

Apart from being easy to prepare, the dried fufu has the advantage of having a longer shelf life, being more convenient to store and less bulky.

Conclusion

When cooked, fufu is a sticky or white, smooth textured product. When properly packaged and stored, it has a shelf life of about 6 months or more.

3. Production of Starch

Starch is soft, white, tasteless powder that is insoluble in cold water, alcohol, or other solvent. It is a polymeric carbohydrate consisting of a large number of glucose units joined by glycosidic bonds.

Objective(s) of the experiment

The experiment is carried to produce starch from cassava

Materials and Equipments

1. Cassava roots

2. Water

3. Knives

Procedure

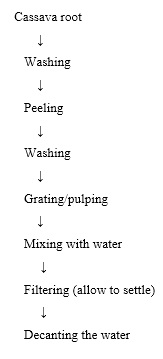

1. Obtain the cassava root, and thoroughly wash to remove any traces of sand that may contaminate the product.

2. After washing, peel the cassava and wash again.

3. Then grate or pulp the cassava as a means of size reduction.

4. After grating the cassava, mix it with water, and filter.

5. Allow it to settle and decant the water.

The procedure is illustrated with the flow diagram below:

Conclusion

Starch production is an isolation of starch from plant sources. It takes place in starch plants. Starch industry is a part of food processing industry which uses starching materials for production of starch derivatives, hydrolysates and dextrin.

Download “Cassava Processing”

Cassava-Processing.docx – Downloaded 0 times – 39.82 KB