Mechanical Properties of Materials

Introduction

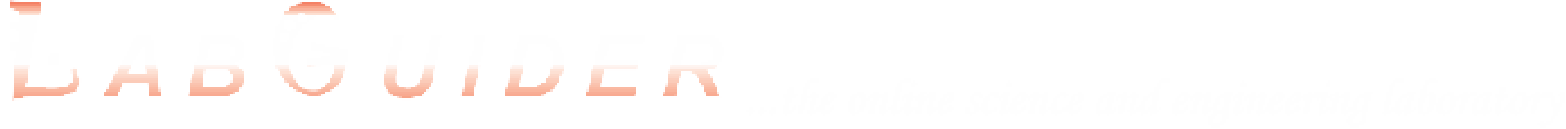

The mechanical properties of a material are investigated if the material is to be used for any engineering purpose and the aim of this is to allow tensile and compressive tests to be carried out on any kind of material using a tensometer.

The mechanical properties of materials include: tensile strength, compressive strength, yield strength, ductility, malleability, toughness, breaking or rupture strength among many others. But ductility, malleability and toughness are fundamental properties in engineering.

Ductility refers to the capacity of a substance to undergo deformation under tension without rupture, as in wire or tube drawing. Malleability is the capacity of a substance to withstand deformation under compression without rupture, as in forging or rolling. Toughness is the ability of a metal to withstand bending or the application of shear stresses without fracture. Since the fundamental engineering properties cannot be expressed in numerical terms, therefore it is necessary to carry out some tests which are related to these properties and which will allow for comparative numerical interpretation. Tensile tests generate data about the plastic and elastic behaviour of materials. The tensile tests are carried out on an instrument called monsato tensometer on which the specimen is stretched and the stress-strain graph is produced. Initially, as the stress increases, the strain also increases uniformly and the process is completely reversible. Over this elastic region, the strain is extremely small and Hooke’s law is obeyed. Beyond the yield stress, the strain increases more rapidly and the process is no longer reversible. This region is called the plastic region.

Objective of the Experiment

The procedure is carried out to determine the mechanical properties of a material to allow tensile and compressive tests to be carried out on the material using a tensometer.

Equipments Needed

- Mechanical tests will be carried out here using a Monsanto Tensometer.

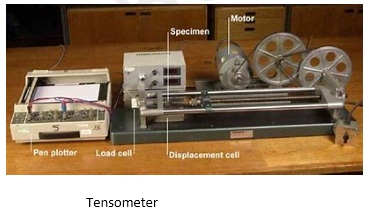

- Vernier Calliper

Procedures

- The first step to carrying out tensile tests is to prepare the samples.

- After the preparation of the samples, the initial gauge length of the sample is taken using a Vernier Calliper.

- The initial diameter is also taken and recorded.

- After taking the initial readings, the specimen should be taken to the tensometer and inserted into the jaws test piece holder and a beam of 2000N used.

- A graph paper is then placed on the chart roller in order to be able to trace out the stress-strain graph, and the mercury indicator set at the 0 mark and the tensile test carried out until the specimen is destroyed. As the handle is being turned, it applies some tensile force on the specimen and also at the same time, the chart roller is rolling and the cursor will be tracing the path of the graph on the graph paper.

- The specimen is pulled until it breaks into two and then the final length and the final diameter is taken.

- The process should be reported repeated for two other specimens

Results and Calculations

For the three specimens, the initial and final lengths and diameters of the specimens are shown below:

Specimen A: COMPOSITION: 0.85 % C, IRON CARBON STEEL, NORMALIZED

Initial length = _________

Final length = _________

Initial diameter = _________

Final diameter = __________

Specimen B: COMPOSITION: 0.85% C, IRON CARBON STEEL, NORMALIZED

Initial length = _________

Final length = _________

Initial diameter = _________

Final diameter = _________

Specimen C: COMPOSITION: 0.85% C, IRON CARBON STEEL, NORMALIZED

Initial length = _________

Final length = _________

Initial diameter = _________

Final diameter = _________

Discussion and Conclusion

From the data collected from the test, one should be able to conclude if the carbon steel samples are indeed good and construction materials as they can withstand heavy loads both live loads and dead ones with reasonable tensile strength. They are also good for making cutting tools since they are hard and do not crumble easily under great force and impact.