Flakiness Index Test

Introduction

Elongation test and Flakiness tests are known as Shape Tests and are performed on aggregate. The Flakiness test is discussed in this procedure.

Click Here to go to Elongation Test

Flakiness index test is used to determine the particle shape of the aggregate and each particle shape being preferred under specific conditions. A flaky particle is the one whose least dimension (thickness) is less than 0.6 times the mean size. These are the materials of which the thickness is small as compared to the other two dimensions.

Significance of Flakiness & Elongation Index

• The degree of packing of the particles of one size depends upon their shape.

• Due to high surface area to volume ratio, the flaky and elongated particles lower the workability of concrete mixes.

• Flaky and elongated particles are considered undesirable for base coarse construction as they may cause weakness with possibilities of braking down under heavy loads.

• BS-1241 specifies a Flakiness index not exceeding 30% irrespective of the aggregate size.

• Maximum permitted Elongated index is 35, 40 or 45% for aggregate sizes 2 ½’’ – 2’’, 1 ½’’ – ¾’’ & ½’’ – 3/8’’.

• Both Flakiness and Elongation tests are not applicable to sizes smaller then 6.3mm i.e. ¼’’ sieve.

Objective(s) of the Experiment

This test is carried out to determine the flakiness index of aggregates

Apparatus Needed

1. Thickness/Flakiness Index Gauge

2. Aggregate sample to be tested

3. Weighing balance

4. IS sieves of the following mesh sizes – 63mm, 50mm, 40mm, 31.5mm, 25mm, 20mm, 16mm, 12.5mm, 10mm and 6.3mm.

Procedures

1. Perform the sieve analysis on the given aggregate sample

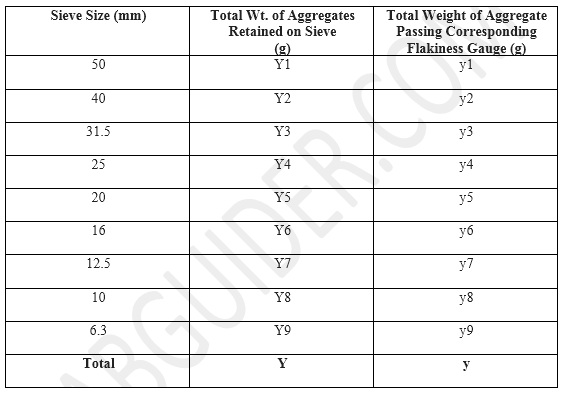

2. Note the fraction of the particles of size ranges of – 63mm to 50mm, 50mm to 40mm, 40mm to 31.5mm, 31.5mm to 25mm, 25mm to 20mm, 20mm to 16mm. 16mm to 12.5mm. 12.5mm to 10mm and 10mm to 6.3mm through the particles retained on the lower sieve sizes (shown on the recording sheet below). Weigh each of these say (Y1, Y2, Y3, Y4….) and record in your sheet. The summation is Y.

3. Take all the fraction separately, gauge them one by one, passing them through the corresponding slot provided in the thickness gauge.

4. Weigh the particles passing each length gauge as y1, y2, y3, y4… The summation is y.

5. Flakiness index is the total weight of the material passing the various length gauges, expressed as a percentage of the total weight of the sample gauged.

Results and Calculations

The sample of the recording sheet is shown below:

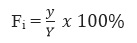

Flakiness index of aggregate in % is calculated as follows:

Where,

Where,

y = weight of particles passing flakiness gauge (grams).

Y = weight of total sample taken for test (grams).

Precautions

1. While sieving, care must be taken that the particles that are chocked in the sieve must not be forced down into the next sieve. Such particles should be pushed back into the same sieve.

2. While placing different fractions on the table, place them some distance apart so that no two fractions may get mixed.

3. Be careful while selecting the opening of the flakiness and elongation gauges for any particular fraction.

Discussion and Conclusion

Limit of flaky particles in the mixes is 30%. If the flaky particles are greater than 30% then the aggregate is considered undesirable for the intended use.

Credits: Samuel Alalade. Obafemi Awolowo University, Ile-Ife, Osun State, Nigeria.